OVERVIEW

Our in-house ETO (Ethylene Oxide) Sterilization chambers are equipped to handle a wide range of materials, ensuring comprehensive sterilisation for various products. These include primary packaging, secondary packaging, surgical consumables, medical devices, and finished dose formulations, among others. With over 20 years of experience in working with ETO sterilization, our dedicated technical team possesses deep expertise in optimising sterilization cycles for different product requirements. This extensive knowledge enables us to collaborate closely with our customers, understanding their unique sterilization needs, and developing custom ETO sterilization cycles tailored to each product. Our commitment to precision and reliability ensures that every item is safely sterilized, meeting the highest standards of quality and compliance.

Designed with the highest safety parameters to ensure the utmost reliability and compliance with industry standards. The facility is equipped with advanced monitoring systems to control temperature, humidity, and gas concentration, ensuring a thorough and effective sterilization process. The cubic capacity of our sterilization chambers is optimized to handle a wide range of products, allowing for flexible batch sizes and efficient throughput. We strictly adhere to safety protocols, including gas leak detection systems and pressure relief valves, to ensure the protection of both personnel and equipment. With this setup, we guarantee that all products undergo a consistent and reliable sterilization process, meeting stringent regulatory and safety requirements.

Our in-house steam sterilization facility is designed to ensure the highest levels of safety and sterility for medical products. Using highly advanced Autoclaves we effectively eliminate contaminants and ensure product integrity while adhering to strict industry standards. This process allows for precise control over sterilization conditions, ensuring consistency and reliability with every batch. It’s an essential part of our comprehensive approach to maintaining the quality and safety of medical devices.

Meticulous control of Critical Parameters

In our sterilization facility, the process is thoroughly controlled to ensure optimal results. Temperature, pressure, humidity, and exposure time are precisely regulated throughout the sterilization cycle. This high level of control guarantees that each product undergoes thorough sterilization without any risk of damage or degradation, ensuring that materials retain their integrity while being completely sanitized. Additionally, process validation is a critical step in our operations. Each sterilization cycle is thoroughly validated to meet specific safety and ecacy standards, ensuring that the process consistently delivers reliable results. This validation provides assurance that all products are sterile and fit for use, aligning with industry regulations and maintaining the highest levels of product quality and safety.

Advanced Monitoring, Documentation & Quality Control

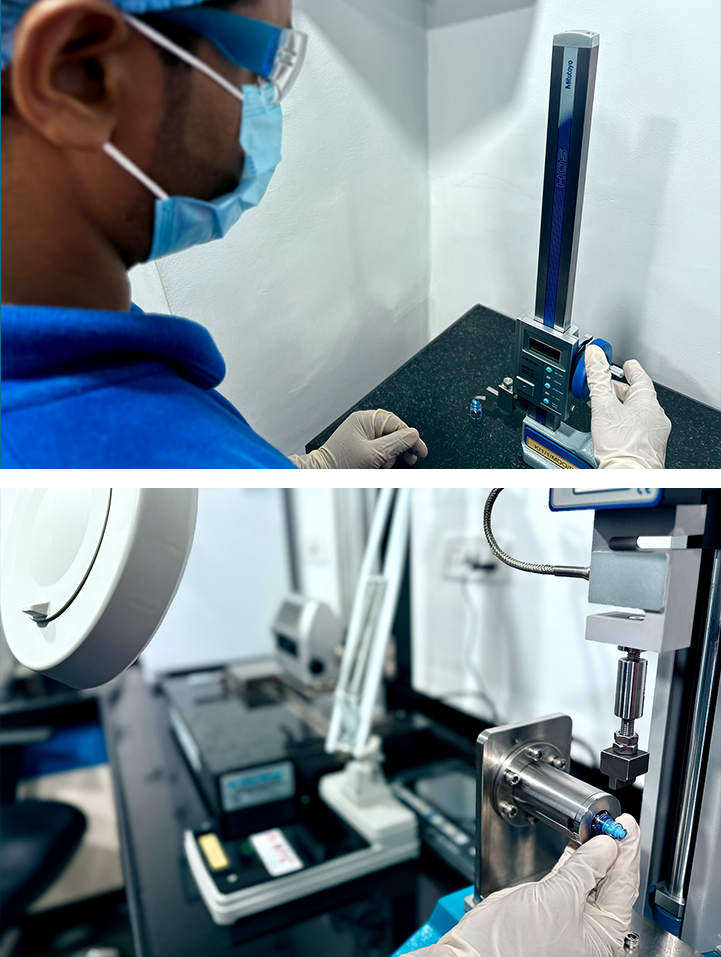

Our sterilization facility incorporates advanced monitoring and documentation systems to ensure the highest levels of quality and compliance. Continuous monitoring is employed throughout the sterilization process, with real-time systems tracking critical parameters such as temperature, pressure, humidity, and exposure time. Any deviations from the established standards are immediately detected and flagged for corrective action, minimizing the risk of errors and ensuring that each cycle adheres to strict specifications. Alongside this, comprehensive documentation is maintained for every sterilization cycle. This detailed record-keeping guarantees traceability and supports full compliance with global regulatory standards, including ISO 9001:2015, ISO 13485:2016 & ISO 11137. By ensuring that each batch is thoroughly documented, we uphold the required safety, sterility, and performance standards, providing our clients with the assurance of reliable, compliant, and high-quality products.

Our sterilization facility upholds the highest standards of quality control and assurance to ensure that every product meets stringent sterility and safety requirements. Each batch undergoes rigorous inspection and testing, including Biological Indicator (BI) and Chemical Indicator (CI) testing, sterility testing, and verification of the sterilization cycle parameters to verify the effectiveness of the sterilization process. Additionally, our commitment to continuous improvement drives the regular auditing and enhancement of our sterilization processes. By incorporating the latest industry standards and best practices, we consistently uphold safety, efficacy, and regulatory compliance, ensuring that our customers receive the highest-quality, fully compliant products.