OVERVIEW

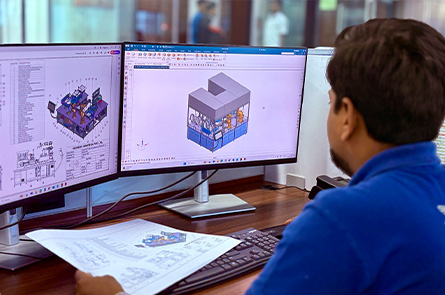

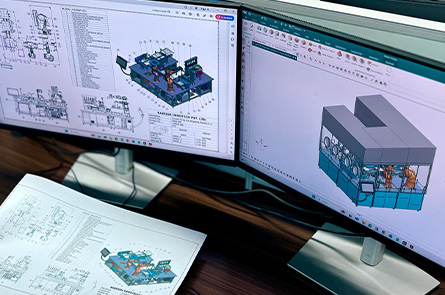

Our Design Department follows a structured, multi-stage approach to creating tools, fabrication components, and machines, throughout the entire process. This approach begins with close collaboration between design engineers and manufacturing teams to understand the project requirements, constraints, and objectives. By integrating manufacturing considerations early in the design phase, we ensure that each part is optimised for the most suitable production method and simplifying the assembly process.

Throughout the design process, our Design Team works closely with the production team to ensure that the design is fully aligned with our manufacturing capabilities, optimising both feasibility and efficiency.

Conceptual Design & Feasibility Analysis

Conceptual Design is critical in transforming initial ideas into actionable plans. This phase begins with Brainstorming and Ideation, where a wide range of design concepts and solutions are generated. Using techniques like sketching, mind mapping, and group brainstorming sessions, the team explores various possibilities, encouraging creativity and innovation. The goal is to identify several potential directions before narrowing the focus.

Next, a Feasibility Analysis is conducted to evaluate the practicality of each concept. This involves assessing factors like technical feasibility, cost-effectiveness, and manufacturability to ensure that the ideas can be realistically implemented within the constraints of the project. A rough analysis is performed to check whether the concepts align with the client’s requirements and operational needs, helping to eliminate non-viable options early on.

Finally, the most promising concept is chosen through Concept Selection, based on the results of the feasibility analysis and the project’s specific goals. This selected concept is then presented to the client for approval before moving forward with further development. During this step, a preliminary design outline is created, and key design parameters—such as size, materials, and performance criteria—are established. This lays the foundation for more detailed design work in the subsequent phases, ensuring that the chosen concept is both innovative and achievable.

Detailed Design & Analysis

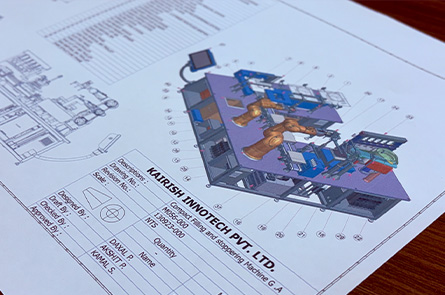

The Detailed Design phase takes the conceptual design to the next level, refining it into a fully developed and production-ready solution. This phase begins with Creating Detailed Drawings, where our design team develops precise CAD models and technical drawings. These drawings include all necessary dimensions, tolerances, material specifications, and assembly instructions, ensuring that every component is clearly defined for manufacturing.

Next, we perform thorough Engineering Analysis to validate the design. This step includes several types of analysis to ensure the product performs as expected under various conditions: