OVERVIEW

Our Liquid Colorant Division specializes in manufacturing high-quality liquid colourants for injection moulding applications, offering unmatched flexibility and precision. We can match any colour to your exact specifications, providing a plastic chip sample of the colour for customer approval before production begins. We offer unparalleled flexibility, enabling us to meet our customers' specific requirements with exactness.

Whether you need small batches or large-scale production, our facility is equipped with advanced mixers and small injection moulding machines in our trial area, allowing us to test and perfect the colour match before full-scale production. We offer customizable pack sizes tailored to your mixing capacity, ensuring efficiency in the production process. Our ability to develop and produce any colour, in both small and large volumes, makes us the ideal partner for small batch manufacturing units as well as large scale industries.

All our products are produced in strict adherence to industry standards to ensure optimal quality. We use only premium ingredients in accurate formulations. Before packaging, each product undergoes rigorous testing by our quality control team to ensure it meets various performance and safety parameters. For secure and tamper-proof packaging, we use the best materials available, ensuring safe delivery to our clients. We pride ourselves on the versatility of our liquid colorants and additives, which are designed to meet the diverse needs of multiple industries. Our products are suitable for a wide range of applications, including packaging, pharmaceuticals, cosmetics, food and beverages, and beyond.

High-Performance Colourants for Diverse Moulding Applications

Our colourants have been successfully used in a variety of moulding applications. They have been successfully used with single and multi cavity moulds which utilise cold runner, semi-hot runner & hot runner systems. We manufacture colourants specifically designed for various materials, such as PP, PC, HIPS, and GPPS, ensuring compatibility across a wide range of polymers. Our colourants are rigorously tested to ensure that even after the autoclave process, there’s no colour leaching or degradation—just long-lasting vibrancy! This ensures superior colour consistency and quality, making our colourants the ideal choice for high-performance injection moulding applications.

Our colourants are fully compatible with pad printing, inkjet printing, and other printing methods, making them ideal for a wide variety of products.

Advanced Manufacturing Process

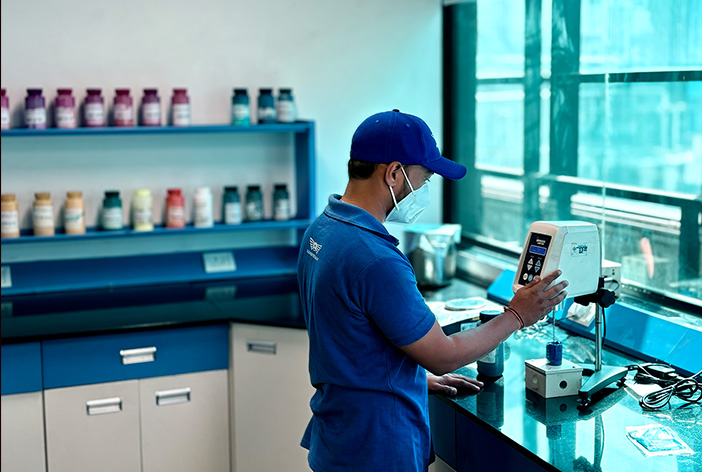

Our Advanced Manufacturing Process is built on cutting-edge technology and a commitment to quality. We utilise top-of-the-line equipment and advanced manufacturing technologies to produce highly consistent and uniform colorants and additives. This ensures that every product, whether it’s a customized colorant or an additive, meets the highest standards of performance and reliability. In addition, we place a strong emphasis on batch control and consistency. Our strict quality control protocols are followed throughout the production process to maintain the integrity of every batch, ensuring that our customers receive the same high-quality product with every order. By combining precision equipment with rigorous quality assurance, we guarantee that our products meet the exact specifications and deliver outstanding results consistently, regardless of order size or frequency.

Excellent Performance, Stability & Safety

We prioritise safety and quality by using safe ingredients in the production of our liquid colorants and additives. Our liquid colourants are completely non-toxic, non-hazardous, and migration-free, with no harmful chemicals or heavy metals like chromium, cadmium, lead, mercury, PBBs, or PBDEs. They are fully approved for food-grade use and have passed rigorous toy safety tests, ensuring they meet the highest standards of safety and quality. Each ingredient is meticulously selected to ensure it meets the highest safety standards, making our products suitable for use across a wide range of industries, including food, pharmaceuticals, and cosmetics.

Fast Turnaround and Reliable Supply Chain

We prioritize fast turnaround and a reliable supply chain to meet the demands of today’s fast-paced market. Our streamlined production processes minimize lead times and ensure timely delivery without compromising quality. Whether it's a large order or urgent request, our strong supplier relationships and advanced logistics keep us on track to deliver on time, every time.

“During the first wave of COVID, we played a pivotal role by supplying millions of vial closures for sealing COVID vaccine vials. When our colorant vendor couldn’t meet the demand, we didn't back down—instead, we took matters into our own hands and started making the colorants in-house. And that's how our journey into creating custom colorants began!”

Knowledge

Nuggets

“Even if you require colourant for just one bag of 25 kg polymer, we are equipped and ready to support your needs—from a single bag to millions of bags—ensuring that you have the right colourant, when you need it.”